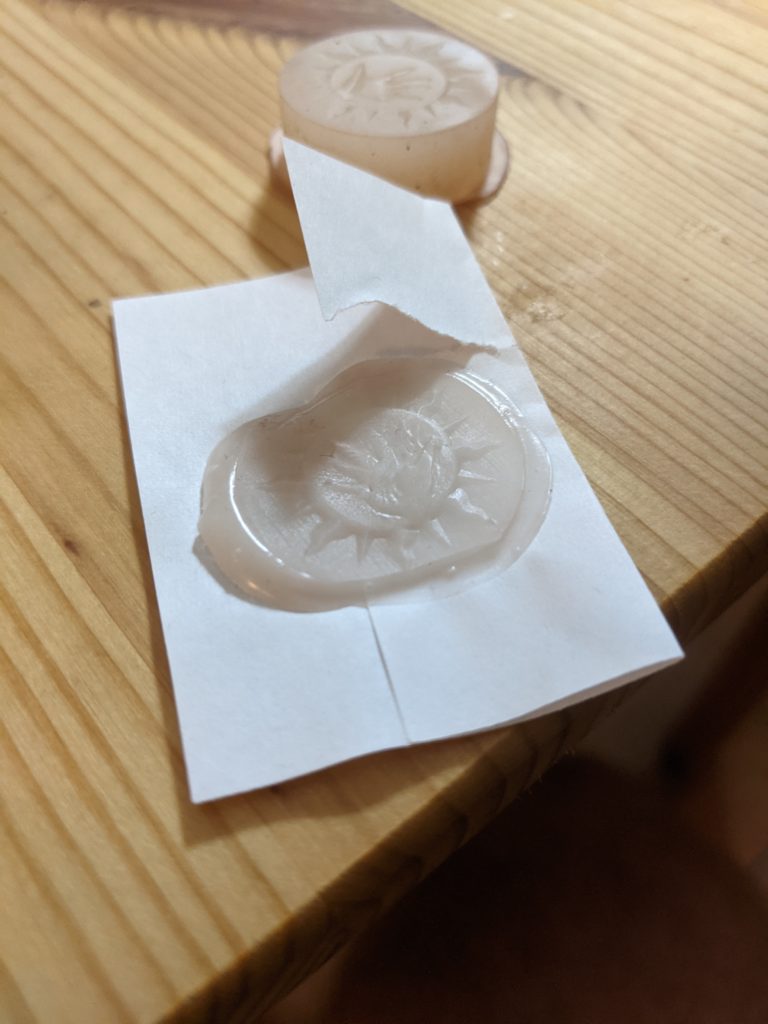

I was a bit interested in making a personal stamp (like for sealing letters), so I threw together a design in Blender, printed it, and cast it in silicone. Just a note, I was incredibly impressed with Blender’s sculpt mode-it felt like I was playing with actual clay, and no matter what I did the result was always a manifold mesh. I have plenty of experience where programs can’t even maintain manifoldness after boolean operations on relatively simple shapes.

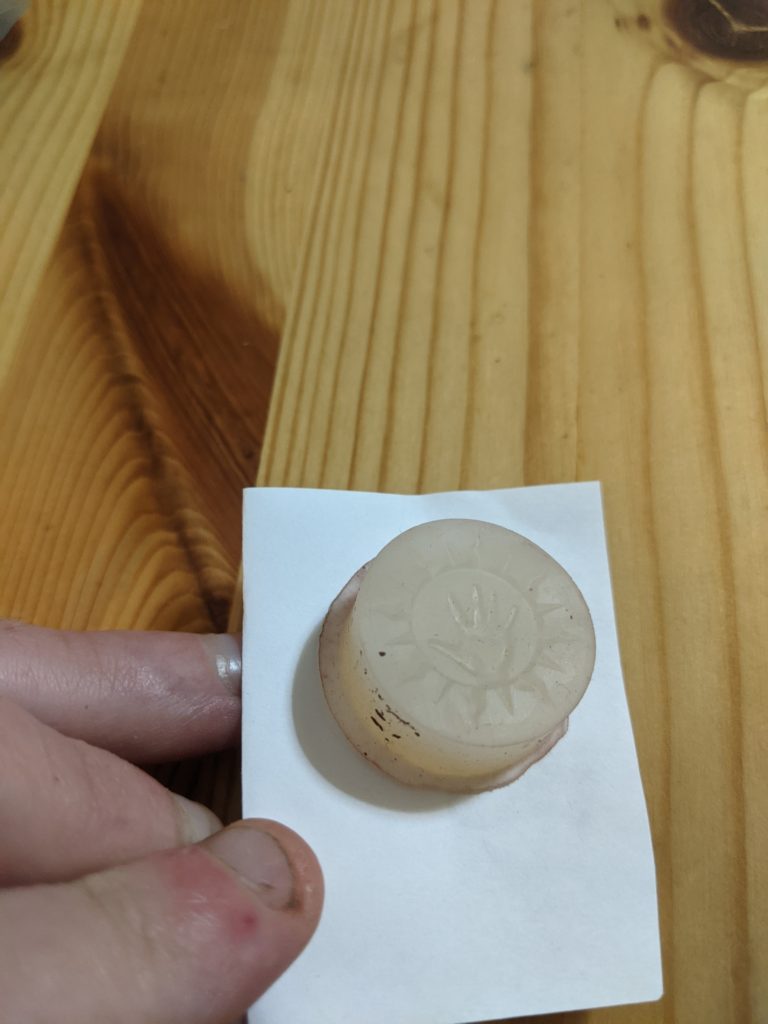

For the stamp itself, I think I used smooth-on’s ecoflex gel (don’t remember now). Silicones are nice because they are generally non-stick, so no extra mold-release is needed. When cast, they often can transfer details finer than the eye can see and this level of detail is used for some types of lithography.

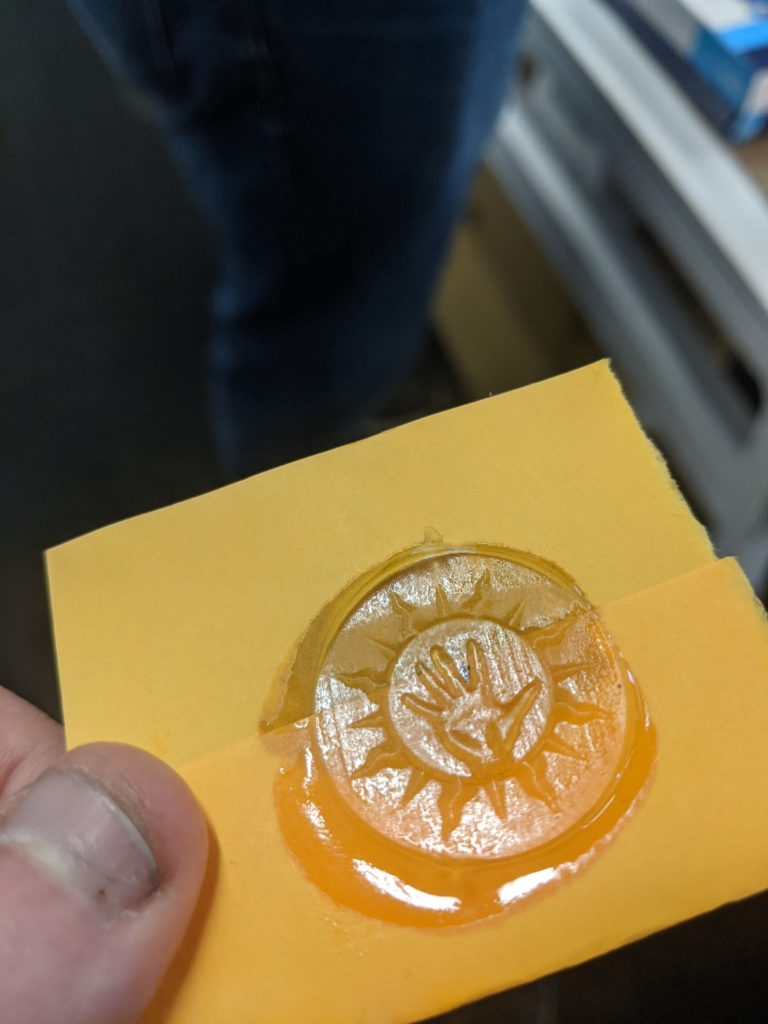

As 405 nm floodlamps and SLA resin were more common where I did this than waxes, I used resin first. I was pretty happy with the results.

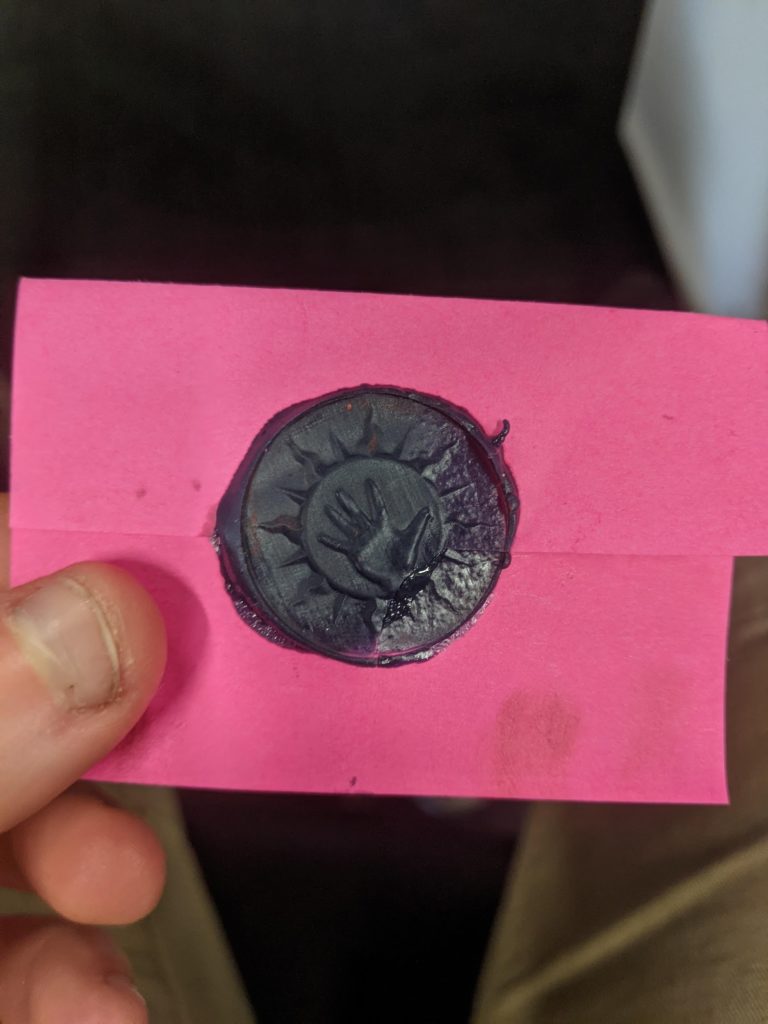

I also tried beeswax (not show), shellac and polycaprolactone, but wasn’t as happy with either of those.

Traditionally, sealing was was made from shellac and beeswax with pigments. Modern sealing wax is literally hot glue. As I didn’t get anything melted to work well I wonder if it was because this used of a silicone stamp instead of a metal one.

I was thinking this would be neat to turn into a small self-contained device, with stamp material (resin or wax), stamp and activator (405nm light or heater). Maybe wedding planners would be interested in it.