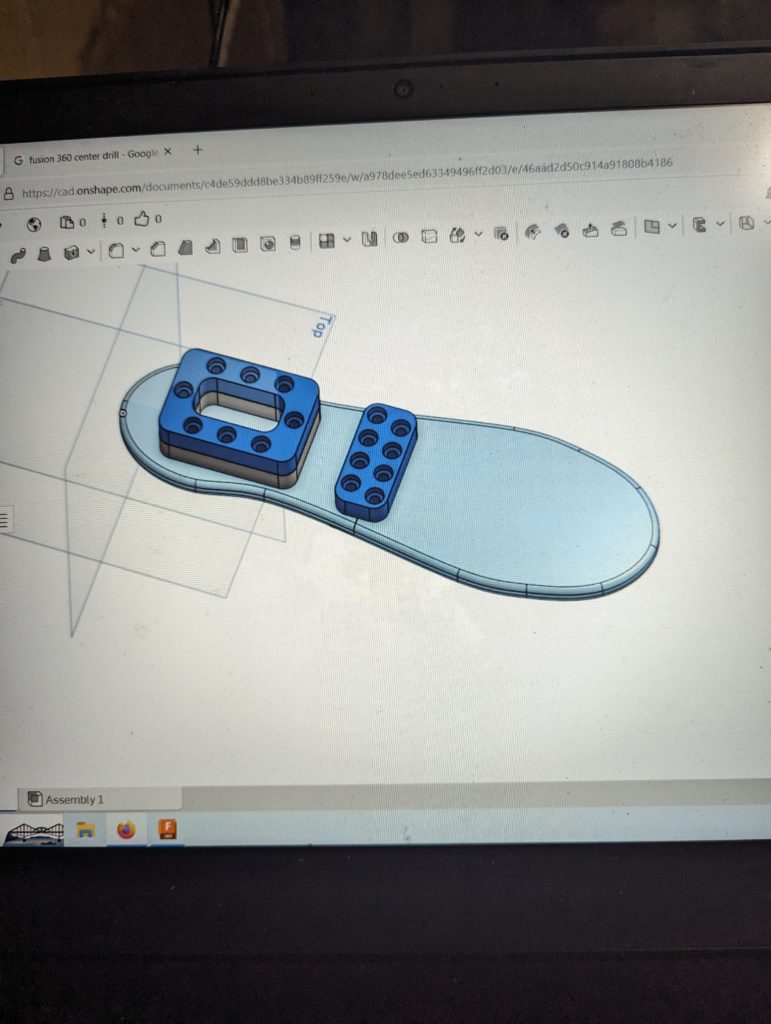

http://ansel.moe requested a larger anvil for driving nails into shoe soles. I had some 6x6x1/4″ (presumably) A36 lying around so I gave it a go in multiple parts. To get the outline I took a lot of profile measurements by hand from an existing anvil and scaled it up.

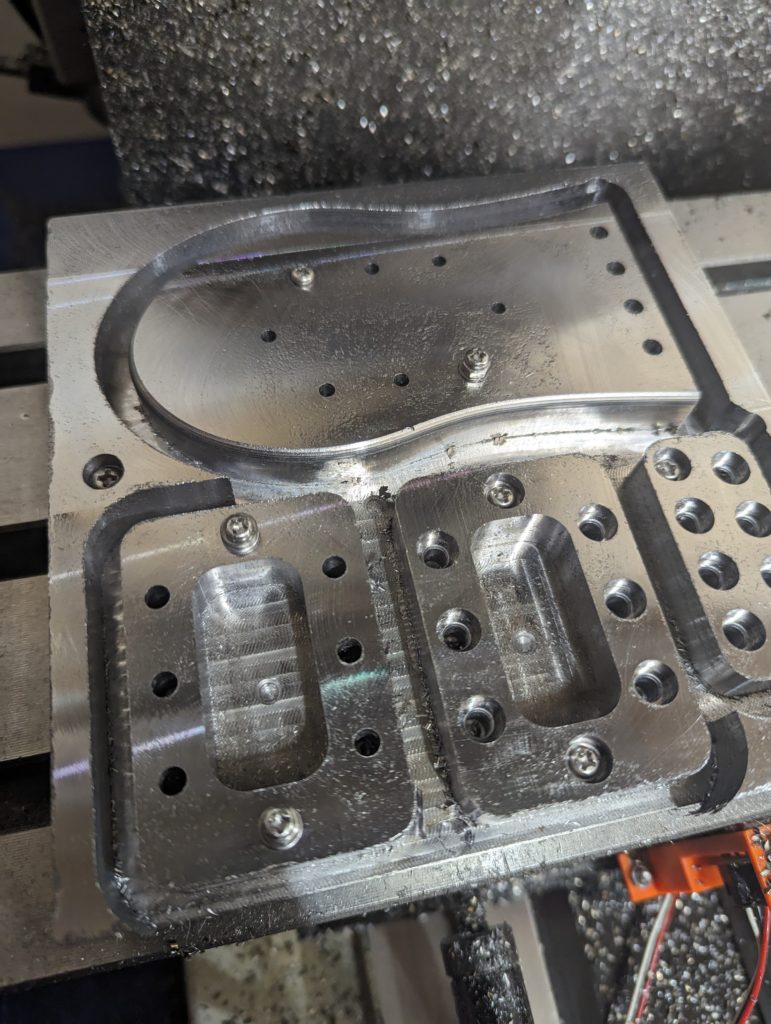

For workholding, I bolted the stock plate onto a sacrificial plate, drilled the stock holes and tapped them, bolted down the indiviual parts to cut out on the stock plate, and then milled them out down to the stock plate. When I had all the pieces, I bolted the post hole in alignment with the sole using an adjustable parallels and a 1-2-3 block, bolted the toe piece on, and clamped it in the vise by the post hole so I could contour the bottom. To help stiffen the overhang, I used a machinist jack, but cutting on the overhang was still noticably louder.