I have recently aquired a Shapeoko CNC router, and with this comes the ability to do 4’x4’x4″ CNC work. I’ve wanted to be able to do CNC leather cutting for a while, but with my mill’s work envelope it never made sense before. To get this set up, I’ve mostly followed methods other people use.

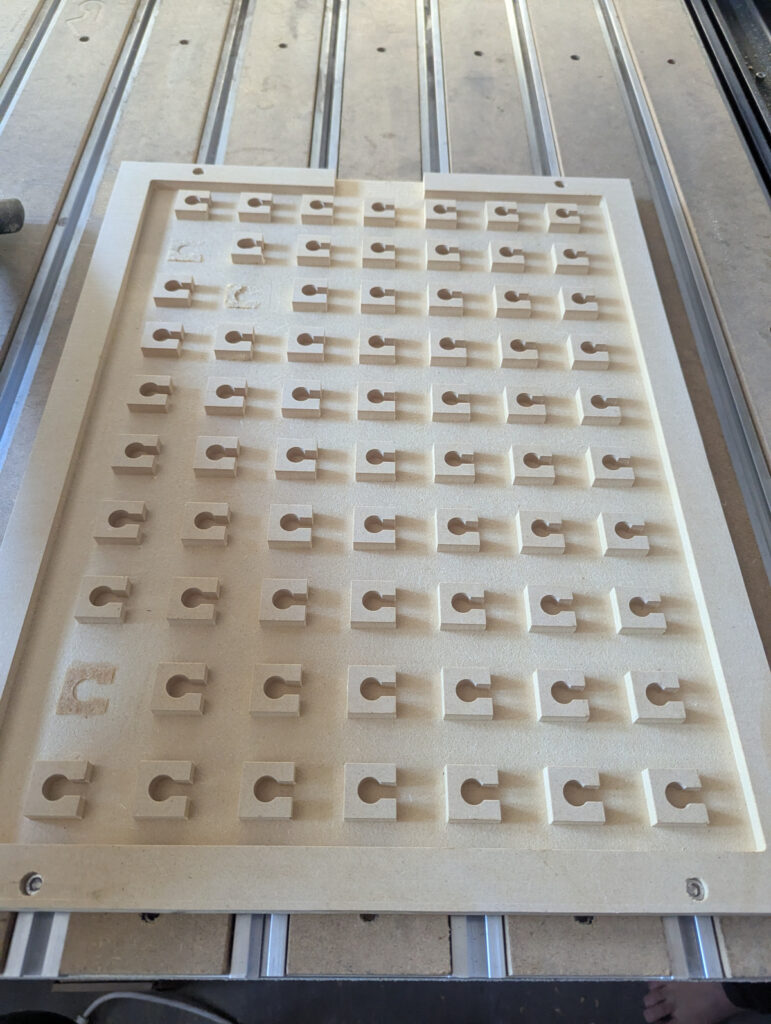

For workholding, I made a vacuum table out of MDF, powered by a shop vac. This consisted of two MDF sheets with a plenum carved between them and supporting structures to prevent the top surface from bowing downward. The non-suction surfaces were sealed with polyureathane varnish. The MDF was permeable enough to apply the required hold-down force for my applications. However, it’s clearly much less good than my real aluminum vacuum table for milling.

You can buy closed-cell performated foam material to improve sealing, and I tried using it but it was worse in this application.

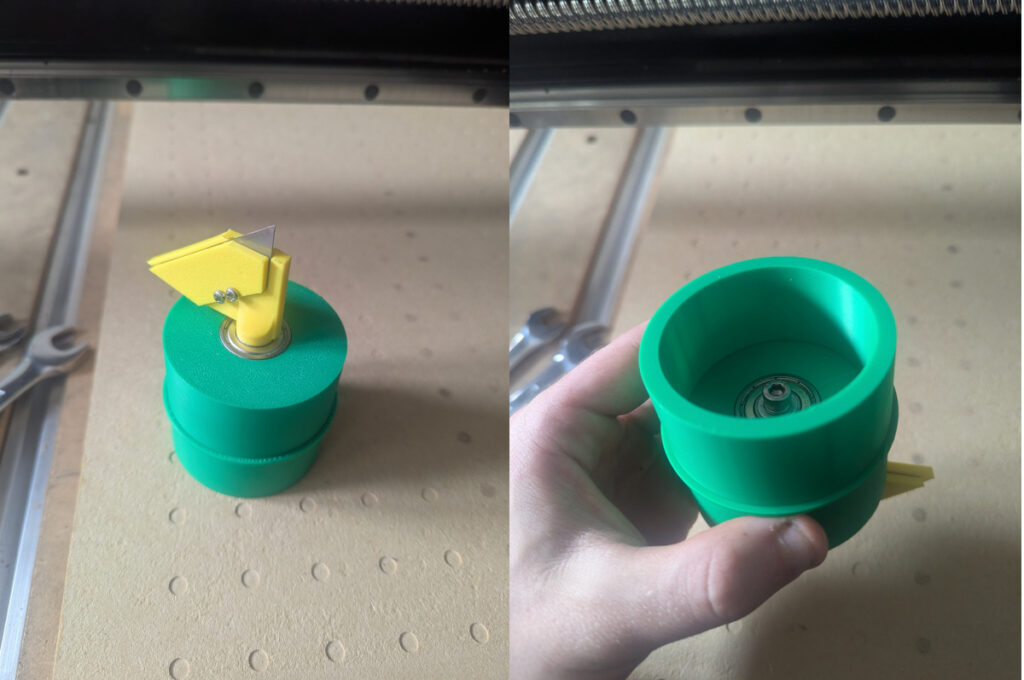

I designed and 3d printed my own drag knife. From a few design iterations it seems very important that the cutting axis of the knife closely aligns with the center of rotation, and that there is only an intermediate amount of rotational friction. The design uses a pair of bearings tensioned together with a bolt/lock washer combo. Adjusting the bolt changes the preload/friction.

There will be a follow up post on software for generating toolpaths, but here’s a child-sized caligae as an example cutout. This was reused leather, so there are previous cut marks on the surface which didn’t go all the way through.