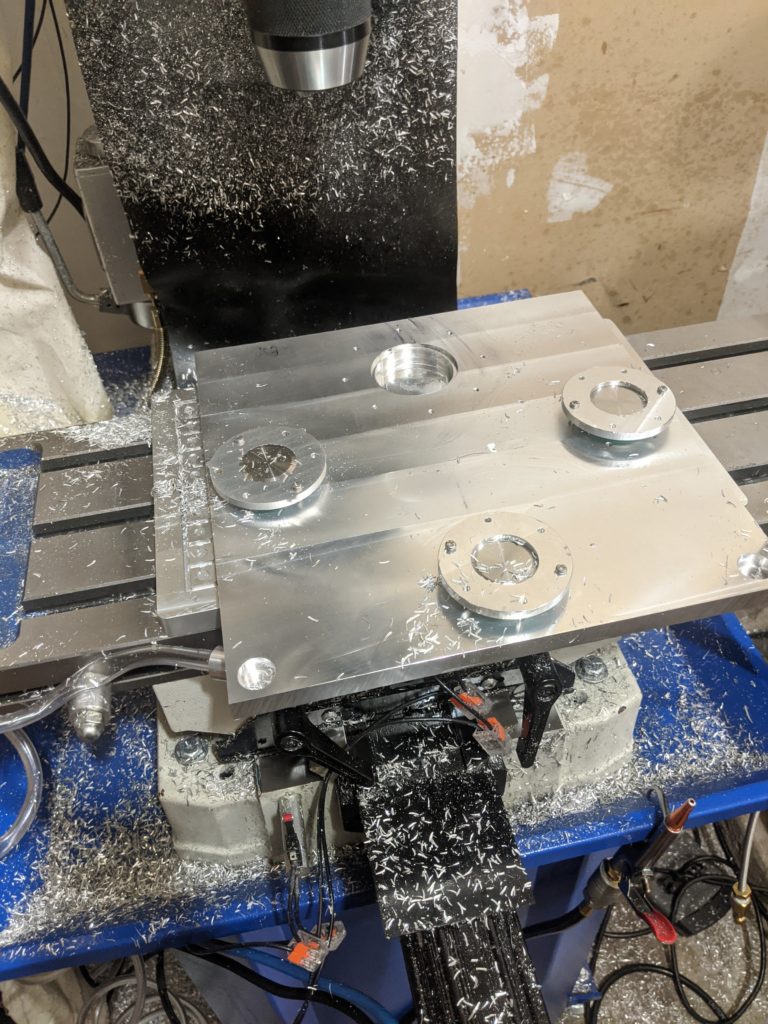

A decent fraction of the things I machine are thin plates, so I bought a Genmitsu vacuum table for my mill. I resurfaced the top and bottom to remove the paint and improve parallelism, drilled bolt holes to mount it into my mill’s T-slots, and added keys for the T-slots to allow me to easily orient the plate so I can place alignment features on the top. On the top I have holes for 3 locating pins so when I flip over parts I can do it with reliable position and orientation.

I’m very glad I bought it–especially since I bought the tormach superfly flycutter. When I need to cut through parts, I leave 200um at the bottom and finish up drills with a hand drill, and use a rotary tool to remove the thin membrane left. I’ve also cut out parts by flipping them over and cutting lightly with a chamfer mill.

The only problem I’ve had so far was I got some metal chips into the vacuum pump and had to clean it out to get good vacuums again. There’s ways to prevent this but in the short term future I’m just going to be more careful.

If I wear this one down enough to need a new one, I’ll probably fully DIY it but it was nice to start from a working product and improve it on my first encounter.