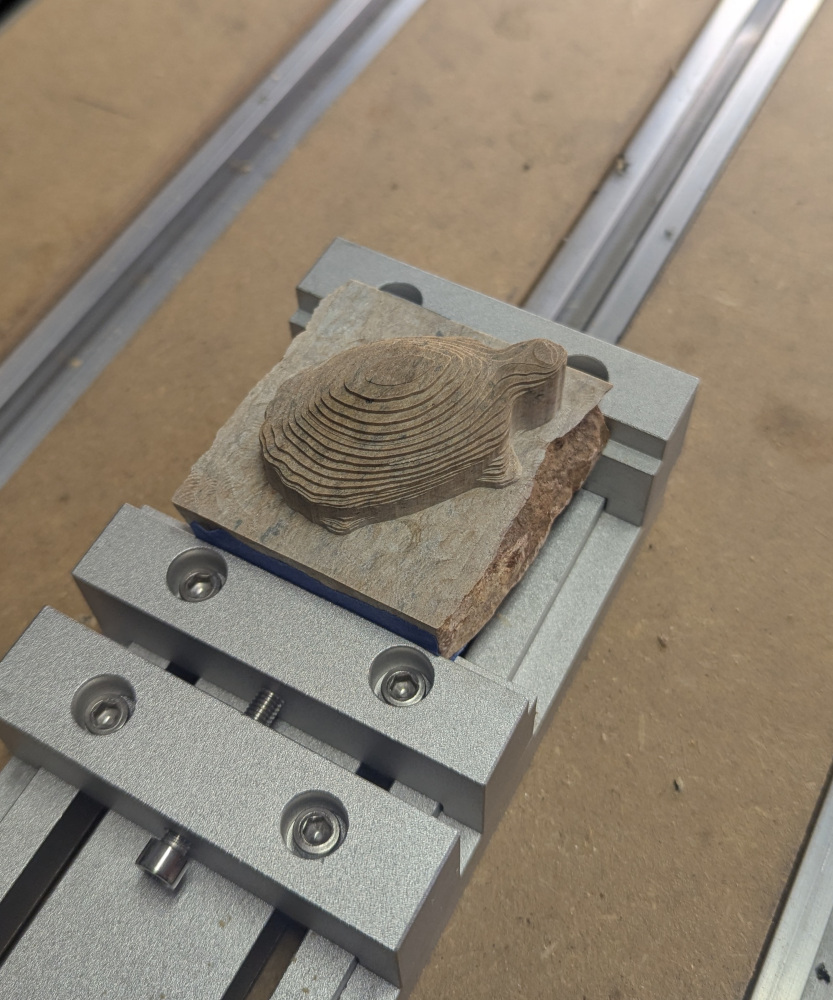

Soapstone is a soft stone with a pleasing handfeel that’s often used for carving into small statues and molds. I’ve been wanting to CNC machine soapstone for some time, but have always avoided it on my mill because I don’t want the dust to damage the mechanics. The Shapeoko has a good dust boot, so I decided to go ahead with it.

For this, I used a 3D adaptive toolpath with a 1/4″ endmill followed by a contour toolpath with a tapered endmill with a 1mm radius ball at the end. My surface speeds were 12,500 IPM and feeds were 0.001 IPT.

I could not grip the stock hard enough in the vise until I tried adding a layer of painters tape along the bottom edge of the stock, which is a trick we occasionally used at my previous employer.

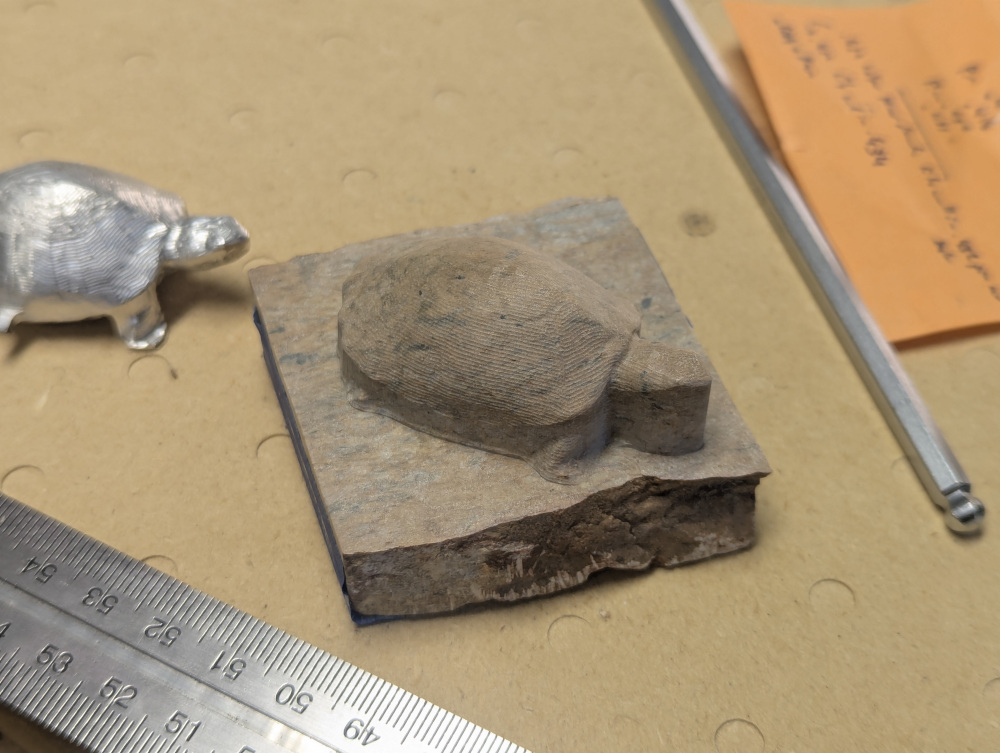

Unfortunately, it would take a heroic effort to machine the bottom of this, which I did for the Aluminum turtle to the side. On that one, I left the model attached by tabs while machining the bottom.

The dust boot was so effective that there was no dust left as evidence.